Autoclave Sterilizer

An autoclave is a machine that employs high-temperature steam and pressure to eradicate microorganisms, including bacteria, viruses, fungi, and spores, from items within its pressurized vessel. Autoclaves serve as essential steam sterilizers in various sectors, including healthcare, laboratories, food processing, and pharmaceuticals. Moreover, autoclaves find application in industrial settings, such as curing composite resins and conducting material testing, particularly within the aeronautical industry.

Types of Autoclave Sterilier

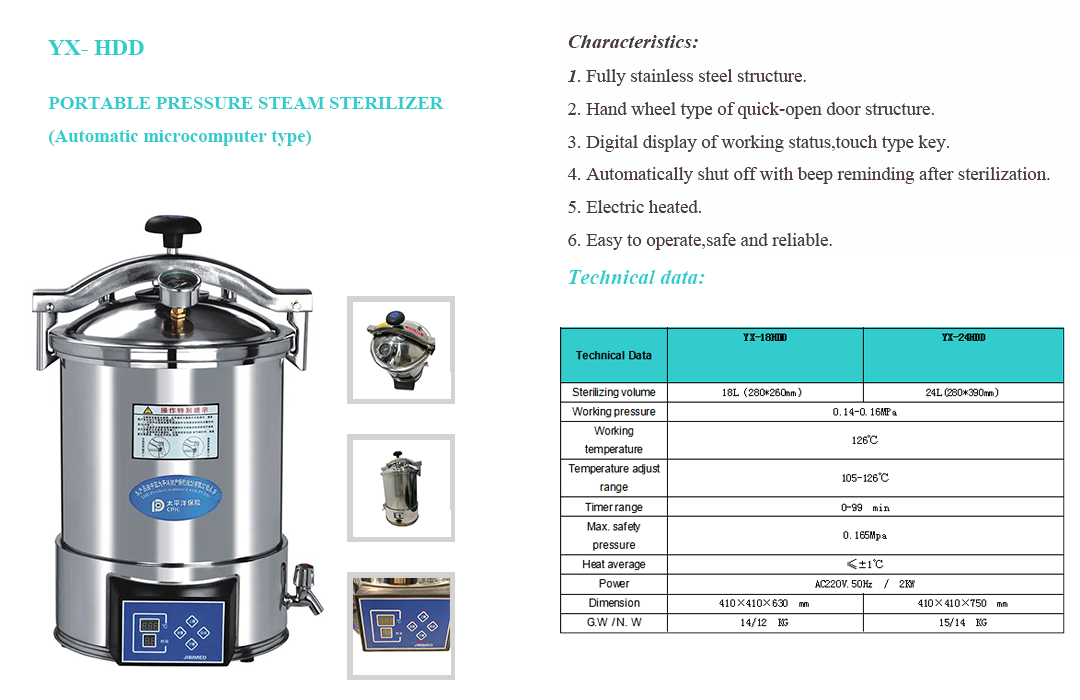

24l Autoclave Sterillization Machine Class B

1. Fully stainless steel structure.

2. Hand wheel type of quick-open door structure.

3. Digital display of working status,touch type key.

4. Automatically shut off with beep reminding after sterilization.

5. Electric heated.

6. Easy to operate,safe and reliable.

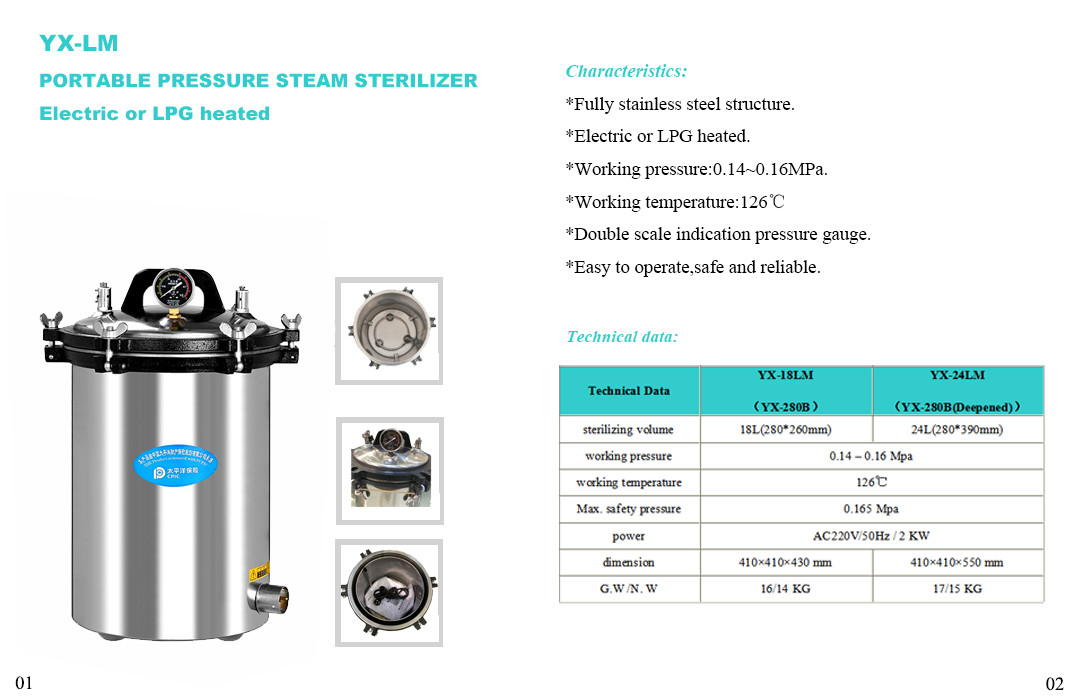

China Table Top Autoclave Class N Series 18/24L Autoclave In Hospital

1. Fully stainless steel structure.

2. Double scale indication pressure gauge.

3. Electric heated.

4. Easy to operate, safe and reliable.

Autoclave Dental Table Top Medical Steam Sterilizer Autoclave Class N

1. Fully stainless steel structure.

2. Hand wheel type of quick-open door structure.

3. Digital display of working status,touch type key.

4. Automatically shut off with beep reminding after sterilization.

5. Electric heated.

6. Easy to operate,safe and reliable.

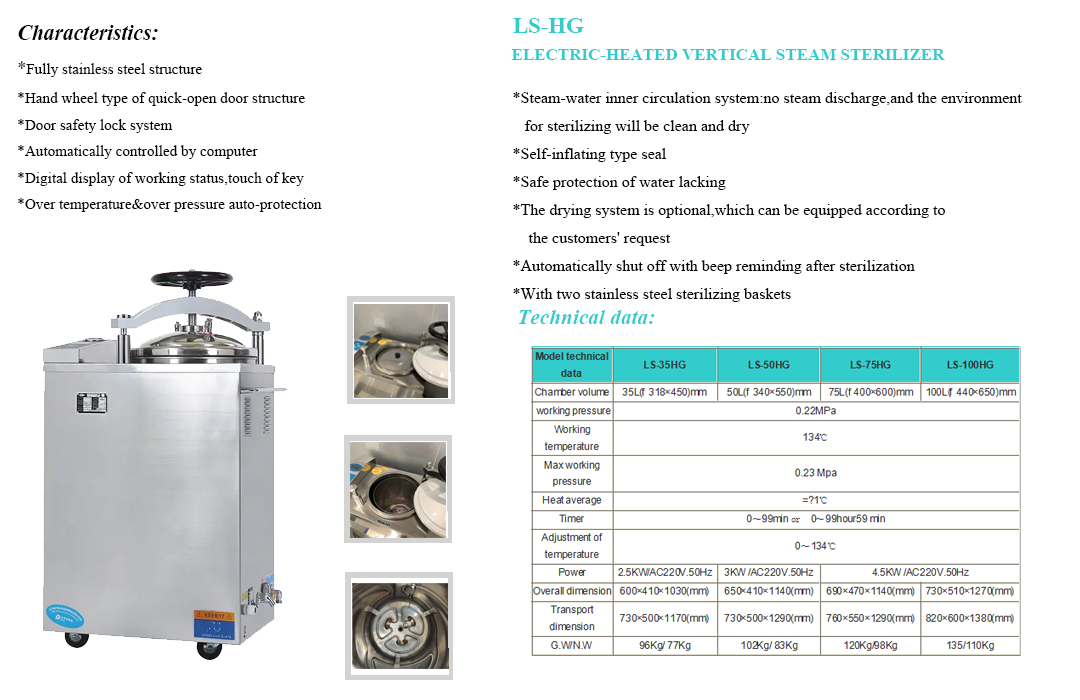

Stainless Steel Dental Surgical Autoclave Steam Sterilizer

ELECTRIC-HEATED VERTICAL STEAM STERILIZER

(Fully automatic microcomputer)

Characteristics:

1. Fully stainless steel structure

2. Hand wheel type of quick-open door structure

3. Door safety lock system

4. Automatically controlled by computer

5. Digital display of working status, touch of a key

6. Over temperature&over pressure auto-protection

7. Steam-water inner circulation system: no steam discharge and the environment for sterilizing will be clean and dry

8. Self-inflating type seal

9. Safe protection of water lacking

10. The drying system is optional and can be equipped according to the customers' request

11. Automatically shut off with a beep reminder after sterilization

12. th two stainless steel sterilizing baskets

75l 100l 120l Automatic Vertical Pressure Autoclave Steam Sterilizer

OPERATION AND DISPLAY

Sterilizing temperature(115~134 ℃)/sterilizing time(0~99 分), for checking the parameter.

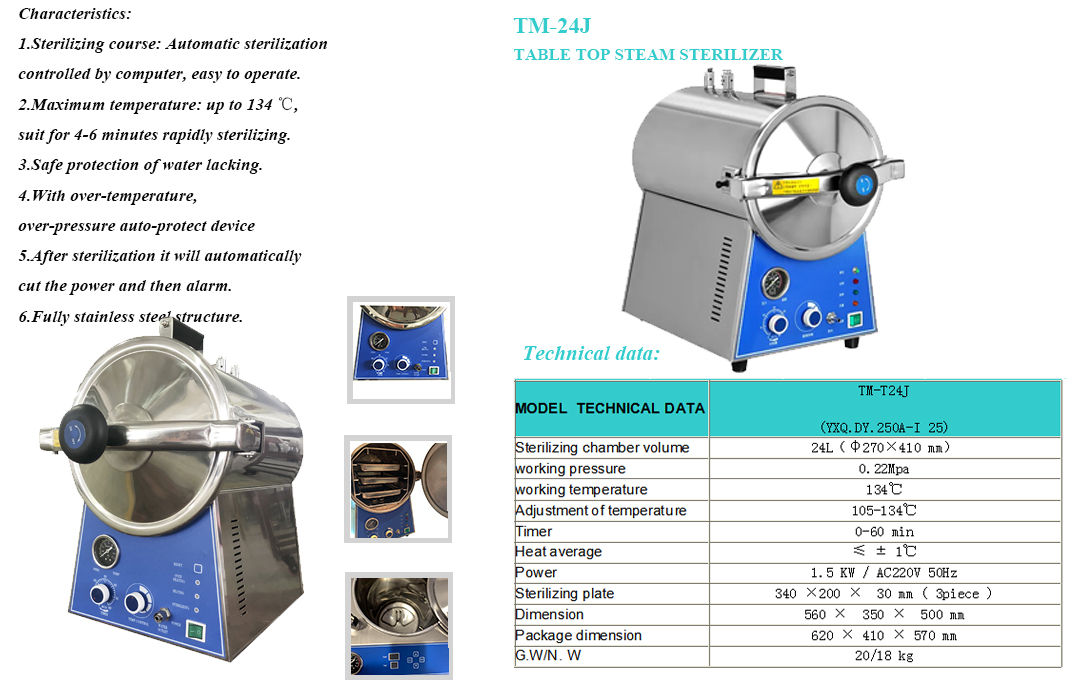

Portable Steam Sterilizer 24 Liters Autoclave 18 Liter Sterilization

1. Sterilizing course: Automatic sterilization controlled by computer, easy to operate.

2. Maximum temperature: up to 134 ℃, suit for 4-6 minutes rapidly sterilizing.

3. Safe protection of water lacking.

4. With over-temperature, over-pressure auto-protect device

5. After sterilization it will automatically cut the power and then alarm.

6. Fully stainless steel structure.

Small Stainless Steel Dental Autoclave Class B For Lab Sterilizer

1. The sterilizing procedure is automatically controlled, it is not necessary to be supervised and used conveniently.

2. At least 3 or more times pulse-vacuum exhausting, which is applied to wrapped or unwrapped objects, and hollow equipment.

3. Drying function.

4. With an inner printer, which records the full procedure of the sterilization.

5. With Bowie&Dick testing function, which is for the steam penetrating testing.

6. Self-testing malfunction, easy to maintain.

7. Safety functions: Safety

8. locking: the steam can not enter the chamber and the unit will alarm when the door is not closed tightly,and the door can not the open when the inner pressure exceeds 0.027mpa.

CE Approved Class B Dental Autoclave Steam Sterilizer

Characteristics:

1. Indicator light indicates working state.

2. For 4~6 minutes rapidly sterilizing.

3. Sterilizing temperature and time can be preset.

4. Steam-water inner circulation system: no steam discharge and the environment for sterilizing will be clean and dry.

5. Over temperature & over pressure auto-protection.

6. Safe protection of water lacking.

7. Exhaust the cool air automatically.

8. With three stainless steel sterilizing plates.

9. The chamber of the sterilizer is made of stainless steel.

10. Automatically shut off with a beep reminding after sterilization.

75l 100l 120l 150l Vertical Pressure Steam Autoclave Sterilizer

VERTICAL PRESSURE STEAM STERILIZER (Digital Display Automation )

Characteristics:

l .Fully stainless steel structure

2.Hand wheel type of quick-open door structure

3.Door safety lock system

4.LCD digital display of working status,touch of key

5.Auto discharge the cool air,and steam discharging auto matically after sterilization

6.Over temperature&over pressure auto-protection

7.Safe protection of water lacking

8.Self-inflating type seal

9.Automatically shut off with beep reminding after sterilization

10.With two stainless steel sterilizing baskets

11. Easy to operate, safe and reliable

12.The drying system is optional, which can be equipped according to the customers request

.png)

Factory Direct Portable Dental Autoclave Pressure Steam Sterilizer

Characteristics

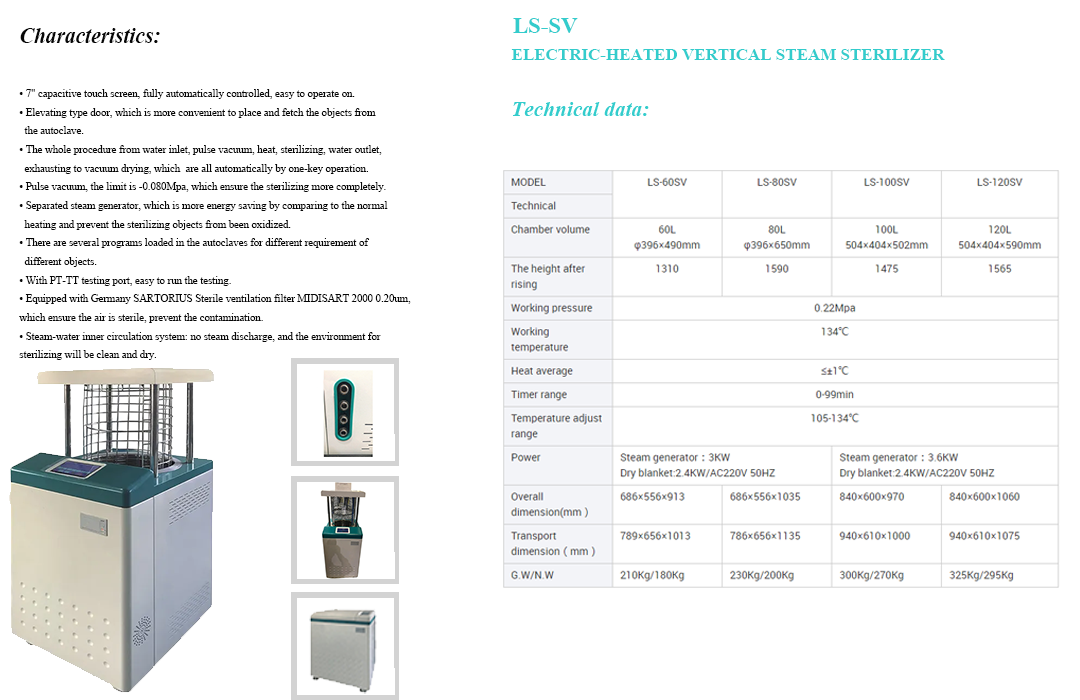

• 7" capacitive touch screen, fully automatically controlled, easy to operate on.

• Elevating type door, which is more convenient to place and fetch the objects from the autoclave.

• The whole procedure from the water inlet, pulse vacuum, heat, sterilizing, water outlet, exhausting to vacuum drying, which is all automatically by one-key operation.

• Pulse vacuum, the limit is -0.080Mpa, which ensure the sterilizing more completely.

• Separated steam generator, which is more energy-saving compared to normal heating and prevents the sterilizing objects from being oxidized.

• There are several programs loaded in the autoclaves for different requirements of different objects.

• With the PT-TT testing port, easy to run the testing.

• Equipped with Germany SARTORIUS Sterile ventilation filter MIDISART 2000 0.20um, which ensures the air is sterile, prevents contamination.

• Steam-water inner circulation system: no steam discharge and the environment for sterilizing will be clean and dry.

Autoclave Sterilization Sterilization Machine Medical And Lab

- The sterilizer software design and manufacturing are conducted according to strict sterilization product technical requirements.

- Operation authority management has a strict managerial class, including a 3 level management system of the manager, maintainer and operator.

- The interlock between the manual program, automatic program and sterilizer door opening makes it impossible to open or close the sealed door when the program is running.

- All alarms and process data can be recorded and printed.

- If the temperature of the inner chamber exceeds safe levels, it is impossible to open the door, thus guaranteeing the safety.

- If the inner chamber pressure is greater than set safety pressure levels, the door will not open, also ensuring safety.

- The operation of this sterilization equipment takes emergency operations into full consideration for abnormal working conditions. This is divided into 4 levels.

.jpg)

Horizontal High Pressure Hospital Sterilizing Large Autoclave Machine

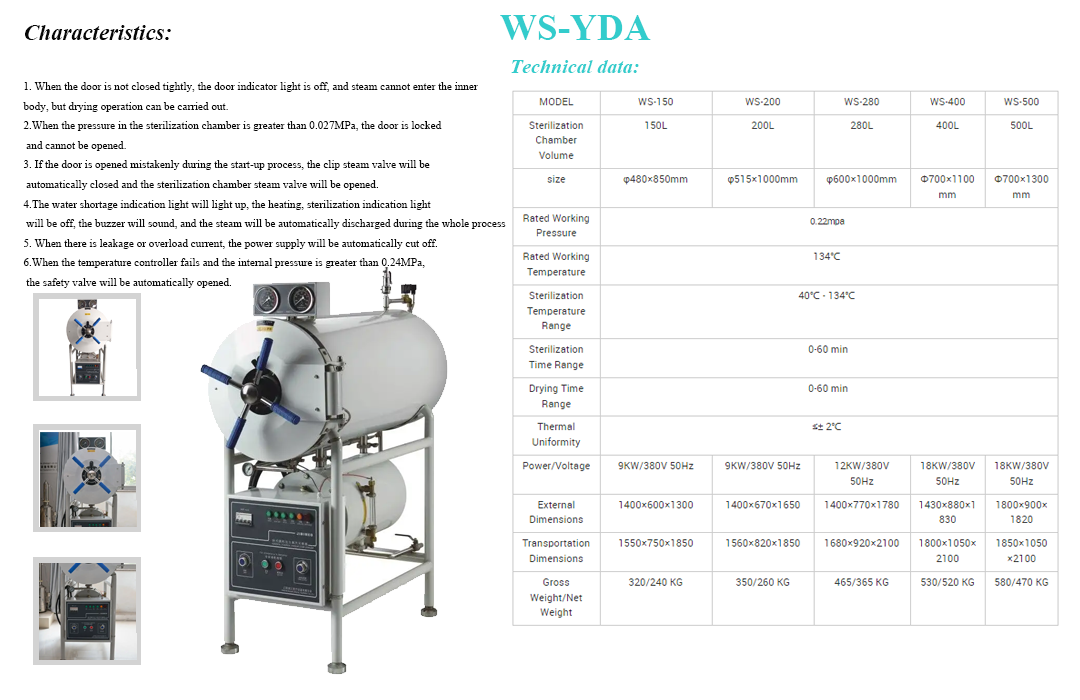

Safety interlock device:

Surgical Instrument 35 75 100L Vertical Automatic Autoclave Sterilizer

Characteristics:

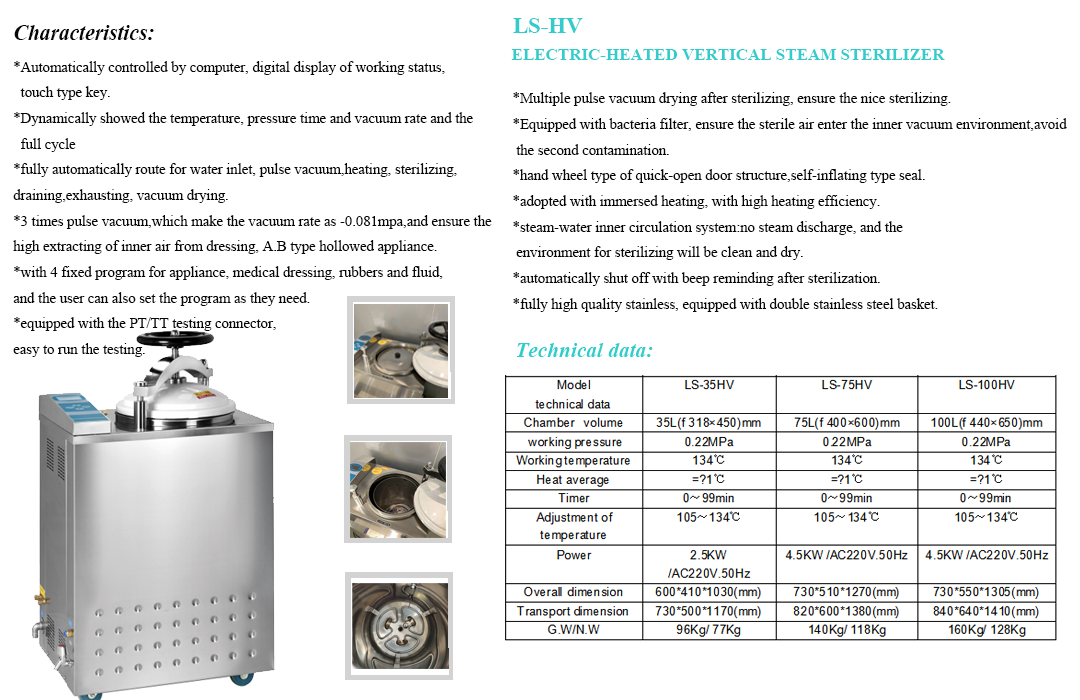

- Automatically controlled by computer, digital display of working status, touch type key.

- Dynamically showed the temperature, pressure time and vacuum rate and the full cycle

- fully automatically route for water inlet, pulse vacuum,heating, sterilizing, draining, exhausting, vacuum drying.

- 3 times pulse vacuum,which make the vacuum rate as -0.081mpa,and ensure the high extracting of inner air from dressing, A.B type hollowed appliance.

- with 4 fixed program for appliance, medical dressing, rubbers and fluid,and the user can also set the program as they need.

- equipped with the PT/TT testing connector, easy to run the testing.

- ........

Autoclave Laboratory Electric Heating Stainless Steel Steam Sterilizer

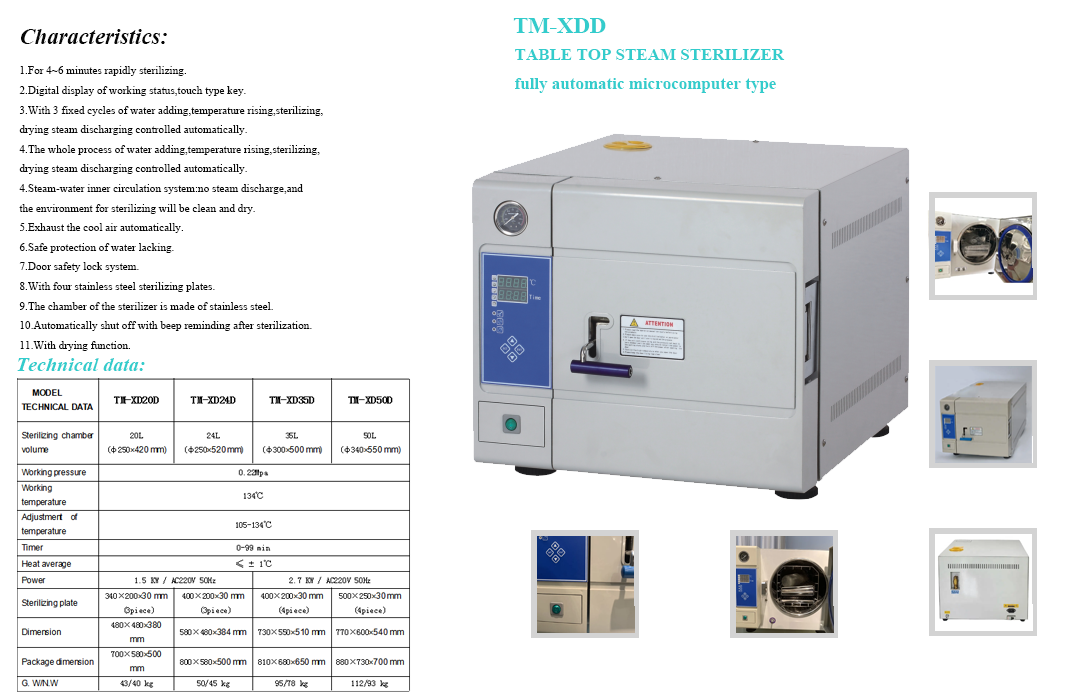

1. For 4~6 minutes rapidly sterilizing.

2. Digital display of working status, touch type key.

3. With 3 fixed cycles of water adding, temperature rising, sterilizing, and drying steam discharging is controlled automatically.

4. The whole process of water adding, temperature rising, sterilizing, drying steam discharging is controlled automatically.

4. Steam-water inner circulation system: no steam discharge and the environment for sterilizing will be clean and dry.

5. Exhaust the cool air automatically.

6. Safe protection of water lacking.

7. Door safety lock system.

8. With four stainless steel sterilizing plates.

9. The chamber of the sterilizer is made of stainless steel.

10. Automatically shut off with a beep reminder after sterilization.

11. With drying function.

Pulse Vacuum Horizontal Type Sterilizer Atuocalve Sterilizer

1. Sterilizing course automatic sterilization controlled by computer, easy to operate.

2. With drying function, suitable dressing drying.

3. With over-temperature, over-pressure auto-protect device.

4. The door opening mechanism cannot be operated until the pressure in the chamber is reduced to 0.027MPa. It can’t be start on if the doesn’t closed well.

5. The safety value will be open automatically when the inner pressure over 0.24MPa, and the steam be exhausting to the water tank.

6. The power will be cut-off automatically, cut-off the water and alarm when the machine lacking water.

7. The chamber of the sterilizer is made of stainless steel.

8. Touch screen color display and with printer.

9. With vacuum pump

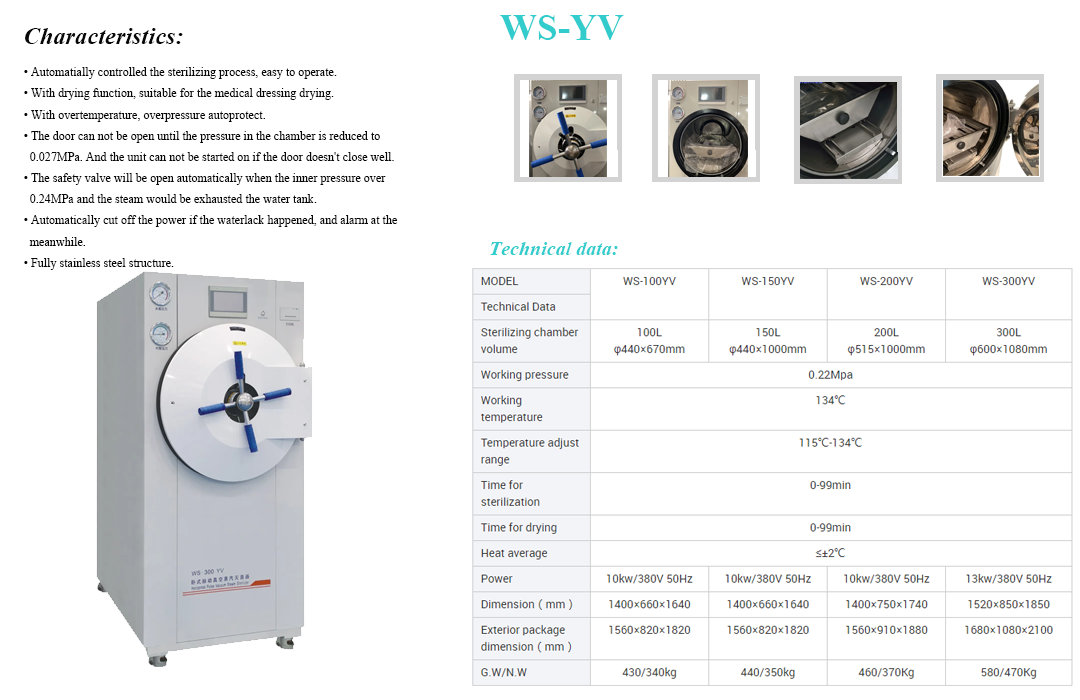

Horizontal Cylindrical Pressure Steam Sterilizer

Characteristics

1. Sterilizing course automatic sterilization controlled by computer, easy to operate.

2. With drying function, suitable dressing drying.

3. With over-temperature, over-pressure auto-protect device.

4. The door opening mechanism cannot be operated until the pressure in the chamber is reduced to 0.027MPa.It can’t be start on if the doesn’t closed well.

5. The safety value will be open automatically when the inner pressure over 0.24MPa, and the steam be exhausting to the water tank.

6. The power will be cut-off automatically, cut-off the water and alarm when the machine lacking water.

7. The surface of the sterilizer is steel coated, the chamber of the sterilizer is made of stainless steel.

8. With printer

Superheated Water Shower Sterilizer-Infusion bottle Sterilizing

During the whole working course, superheated water operates in a relatively sealing cyclical system,which has series of advanyages,high heat efficiency,good temperature evenness,stable temperature adjusting range,etc.Besides,this equipment also effectively,good temperature evenness.stable temperature adjusting range,etc.Besides,this equipment also effectively prevents second pollution during working with anti-pressure protection device.lt can be applied widely to high-and-low temperature sterilizing operation on liquid in glass bottles.Ampoule bottles,plastic bottles, plastic packs,etc,in pharmaceutics.it is also suitable for foodstuff industery to sterilize all kinds of sealing package,drinks,cans.

Dry heat sterilizer

Technical Characteristics

The advanced technology can realize the dynamic 100-grade and superior temperature uniformity for the dry-heat sterilization ovens

* All the inner portion of the cavity which is possible to contact the article adopts the imported 316L stainless steel material.

* The outer surface adopts the imported 304 stainless steel material, and a new manufacturing technology is used to comply with GMP requirement and make the appearance more simple and beautiful.

* The special heat-insulating type is used to ensure the appearance temperature of products ≤ room temperature +15℃.

* The inner cavity room is welded well by adopting TIG welding technology, the four corners of inner cavity adopt arc transition structure, and they can be cleaned easily without dead corner.

Ampoule Leak Sterilizer- Injection Solution & Ampoule Sterilizing

Pure Steam Sterilizer-Biological Sterilizing

uring the biotic pharmaceutics process, strict aseptic conditions and heat-free sources are crucial. Consequently, there is a heightened demand for sterilizers. In line with GMP's rigorous standards and utilizing high-quality materials, we offer the following products for biotic pharmaceutics: aluminum kegs designed for various antibiotics, their rubber covers, and other applications with stringent requirements.

The structure of this product series features double layers. Pure steam fills the inner layer during operation, while the outer layer utilizes standard boiler steam. This design allows for dual functionality, including vacuum exhaust and drying, meeting the exacting needs of the biotic pharmaceutics industry.

.jpg)

Multtifuonal Chinese Medicine Sterilizer-Herb & Powder Sterilizing

Former sterilization methods for Chinese herbal medicine typically involve cobalt 60, ethylene oxide, alcohol, microwave, ozone, and more. However, these methods often struggle to ensure the preservation of the medicine's properties, leading to residues or increased costs. Through testing, steam has been identified as the most suitable method for sterilizing herbal medicine.

To address this need, we have designed a series of sterilizers with a horizontal and rectangular shape. By employing in-and-out steam heating, the cabinet's space is fully utilized. Within the cabinet, special damp-proof equipment eliminates lumps that may occur in herbal powder due to traditional steam sterilization methods. These sterilizers are specifically tailored for use in Chinese pharmaceutical factories.

Rotary Super Water Sterilier- Suspension& Emulsion Sterilizing

with the advancement in the pharmaceutical and food industries, the demand for rotary sterilizers is increasing. These sterilizers operate based on the conventional principle of using saturated steam for sterilization. However, what sets them apart is the ability of the sterilizing cart to rotate forward or backward at an adjustable speed. This dynamic feature is achieved through a magnetic drive system, ensuring compliance with GMP standards.

Our meticulous design and refined processing technology guarantee that your products receive the highest quality sterilization results.

Infusion bottle Sterilizing Ventilate Sterilizer

This series utilizes the sterilization principle of mixed pressure by air and steam. High-energy, double-speed air blowers drive a mixed gas to circulate forcefully within the sterilizing products. Primarily designed for sterilizing products that require drying of containers and packages after cooling (e.g., checking, labeling, packing), it caters to various industries. This system is ideal for sterilizing PE or PP plastic bottles, as well as PVC or compound plastic soft package liquids.

Rapid Cooling Sterilizer-Infusion bottle Sterilizing

Description: This series introduces a new-generation pressure steam sterilizer that is automatically controlled by a program and features double rectangular stainless steel doors. It can draw and record temperature and time curves automatically, as well as preset, display, and print F values.

Control System: The equipment utilizes a high-performance PLC testing control system with two operating modes (manual and automatic). It also includes standard interfaces compliant with GMP standards.

Advanced Functions:

- Pre-vacuum: Ensures thorough sterilization.

- High-temperature quick sterilization: Rapidly sterilizes products.

- Quick cooling after sterilization: Enhances efficiency and product safety.

- Special anti-pressure protection device: Safeguards against pressure-related issues.

Sterilization Capability: This equipment can reliably sterilize various damp-heat resistant products in bulk, bottles, cans, and soft packages.

Wetting Maching Of Chinese Traditional Medicine-Herb & Powder Sterilizing

Description: The wetting machine of Chinese Traditional Medicine operates on the principle of utilizing the excellent penetrability of vapor. The vapor at low temperatures quickly permeates the inner medicinal materials placed in a vacuum, effectively softening them.

Functionality: This machine is a novel device used in the production and processing of Chinese Traditional Medicine, facilitating quick and complete penetration of medicinal materials. It helps in preserving the medicinal composition to a great extent while enhancing the quality of medicinal slices. Following vapor wet treatment, the medicinal slices have low water content and can be easily dried.

Design and Features:

- The machine is designed and manufactured in compliance with pressure vessel standards.

- The door mechanism of the device incorporates patented technology, providing excellent sealing performance and operational convenience.

- Besides wetting Chinese Traditional Medicine, the machine can also be used for vapor sterilization, offering a wide range of applications in the production of Chinese Traditional Medicine materials.

Vertical Pressure Steam Sterilizer

Vertical Pressure Steam Sterilizer is electric heating and automatic-control pressure type.With advantages of reliable sterilizing result, convenient operation,power saving,low price,high quailty, etc.it is and ideal instrument for medical and research units to sterilize operation equipment ,dressings, utensils culture medium and so on.

Desk-type Pressure Steam Sterilizer

desk-type fast autoclave is automatice micro-controlled minitype disinfequipment with reliable safety system,which is designed for a disinfection of surgical apparatus,dental apparatus,medical stuff,medical liquid,medical glass,syringe as well as food which are subject to high Pressure and steam.It is suitable for disinfection and sterilization in hospita and clinics, scientific research institutions of factories, especially in operation room that requires quick supply of sterile articles.

Clean Machine

Clean Machine adopts PLC control system and human-machine interface, and full automatic control carried out on the whole process. It is easy to operate. The machine is widely used in the pharmaceutical factory, cosmetic and food industries to wash tanks.

Structure & Capability & Characteristics

Reliable and stable micro-computer automatic control PLC + touch screen control.

Pneumatic translational door, easy to operate, flexible.

Elegant stainless steel decorate cover

Sterilizing transferring cabin

Sterilizing Transferring Cabin:

The sterilizing transferring cabin features a PLC control system and a user-friendly human-machine interface. It is equipped with a built-in electric heating steam generating plant for efficient operation. The fully sealed door ensures the complete sterilization process is under automatic control. This equipment finds extensive applications in pharmaceutical factories, hospitals, biological laboratories, and more.

Main Parameters:

Control System: PLC

Interface: Human-Machine Interface

Heating System: Electric Heating Steam Generating Plant

Automation: Full Automatic Control

Applications: Pharmaceutical Factories, Hospitals, Biological Laboratories

Utilities Required:

Power Supply: [Specify Voltage/Phase]

Water Supply: [Specify Pressure/Quality]

Steam Source: [Specify Type/Pressure]

Ventilation: [Specify Airflow Requirements]

If you have specific details regarding the main parameters and utilities needed, feel free to provide them for further elaboration.

Washing Sterilizer

Washing Sterilizer: The washing sterilizer is equipped with a PLC control system and a user-friendly human-machine interface, facilitating full automatic control throughout the process. Its intuitive operation makes it easy to use.

Applications: This machine is designed for washing and sterilizing drums and cages in pharmaceutical factories, biological research institutes, animal laboratories, and similar settings.

Size & Utilities:

- Dimensions: [Specify Size/Dimensions]

- Control System: PLC

- Interface: Human-Machine Interface

- Automation: Full Automatic Control

- Suitability: Drum and Cage Washing/Sterilizing

- Applications: Pharmaceutical Factories, Biological Research Institutes, Animal Laboratories

Utilities Required:

- Power Supply: [Specify Voltage/Phase]

- Water Supply: [Specify Pressure/Quality]

- Steam Source: [Specify Type/Pressure]

- Ventilation: [Specify Airflow Requirements]

For a more specific description of size and utility requirements, please provide detailed specifications.

STERILIZATION WASHING MACHINE

Description: This series represents a new-generation steam sterilizer that also operates as a washer. The process involves seven steps: soaking, washing coarse, washing fine, dehydration, sterilization, drying, and cooling. By precisely controlling temperature, pressure, and time, dressing materials are rapidly and effectively sterilized and dried.

Features:

- Multifunctionality: Acts as both a sterilizer and a washer.

- Seven-Step Process: Soaking, Coarse Wash, Fine Wash, Dehydration, Sterilization, Drying, and Cooling.

- Efficient Sterilization: Ensures quick and effective sterilization of dressing materials.

- Applications: Suitable for pharmaceutical factories and hospitals.

- Versatility: Functions not only as an autoclave but also as a washer.

This product offers advanced capabilities for sterilizing and washing dressing materials, catering to the needs of pharmaceutical facilities and hospitals with its dual functionality.

Multifunctional Washing Sterilizer

Multifunctional Washing Sterilizer: The Multifunctional Washing Sterilizer features a PLC control system and a user-friendly human-machine interface, enabling full automatic control throughout the entire process. Its ease of operation makes it user-friendly.

Applications: This machine is designed for washing and sterilizing instruments in pharmaceutical factories, biological research institutes, animal laboratories, and similar settings.

Key Features:

- Control System: PLC

- Interface: Human-Machine Interface

- Automation: Full Automatic Control

- Versatile Functionality: Washing and Sterilizing

- Suitability: Instruments Washing/Sterilizing

- Applications: Pharmaceutical Factories, Biological Research Institutes, Animal Laboratories

If you have specific requirements regarding size and utilities or need more detailed information on any aspect, please feel free to provide additional details for further clarification.

Swing Sterilizer

Description: This machine represents a high-tech integrative product that fully complies with GMP standards. Primarily used for sterilizing suspensions and emulsions, it operates smoothly with excellent sealing throughout the entire process. The loading system is driven by the drive unit, ensuring efficient operation.

Key Features:

- Technology Integration: Incorporates advanced technology.

- GMP Compliance: Fully meets Good Manufacturing Practice requirements.

- Sterilization Focus: Specializes in suspensions and emulsions sterilization.

- Stable Operation: Ensures stable performance during operation.

- Sealing Quality: Provides excellent seal integrity.

- Drive Unit: Propels the loading system for enhanced efficiency.

- Precision Design: Offers precise design and exquisite processing technology.

- Optimal Sterilization Results: Ensures the best sterilization outcomes for your products.

If you have any specific requirements or need further details on particular aspects of the machine, feel free to provide additional information for a more tailored response.

Osciliating Sterilizer

Description: This high-tech integrated machine is designed to meet GMP standards effectively. It specializes in the sterilization of suspensions and emulsions. Throughout operations, the machine ensures stable performance with reliable sealing. The loading system moves back and forth at a consistent speed.

Key Features:

- Technology Integration: Incorporates advanced technology.

- GMP Compliance: Fully meets Good Manufacturing Practice requirements.

- Sterilization Focus: Specializes in suspensions and emulsions sterilization.

- Stable Performance: Runs smoothly and consistently.

- Sealing Quality: Ensures a reliable seal throughout the process.

- Loading System: Moves back and forth at a regular speed for efficient processing.

- Precision Design: Employs precise design and exquisite processing technology.

- Optimal Sterilization Results: Guarantees the best outcomes for your products.

If you have specific details or additional requirements that need to be addressed, please provide more information for further customization.