Environment EO Concentration Detection System

The system tests the EO concentration of the monitoring points by sampling pump polling, to establish the EO concentration system for the whole workshop.

Fewer EO sensors are needed, 4 sensors at most, 2 of PEL and 2 of LEL for the whole workshop, with inspection of many points. Normally: 8 points, 32 points.

The chamber above 50m3 meets GMP standards and 21 CFR Part 11 standards.

Compliance with EN1422-2014, YY0503-2016.

Compliance with ISO11135-2014, and ISO13485-2016.

Data Record

In accordance with ANSI/AAMI/ISO 11135, it is required for temperature and humidity levels be monitored during an EtO/EO sterilization process. Data loggers can be used to validate these parameters to ensure an environment in which sufficient sterility levels are achieved.

Door Control

Patent No.: 201xxxx73506.6

Conforms to the latest IS011135-2014 standard.

One door controller controls one door independently, basically without the control of other PLCs or devices.

The gate can be operated as an independent device or as a slave station controlled by the central control.

Stop and maintain any position of the door function.

Touch screen display, showing the door status, temperature, pressure, humidity, and other sterilization operation parameters inside the sterilization chamber.

Local Control Box

.webp?x-oss-process=image/auto-orient,1/interlace,1/resize,m_lfit,w_2560,limit_0/quality,Q_75/format,webp)

Strong anti-interference ability: _x000b_The signal wire directly enter into local control box, it avoids effectively the interference of power cable to signal cable.

Distributed design: It's easy to install on site, save a lot of signal wires, labor and tine expenses for installation workers.

Modular design: The local box does not involve any control of power components, so it is very convenient to realize the standardization of the whole sterilization control system and realize the modular design and production.

Printer

HP M427DW 427FDW

Water Tank

Multi-function heating mode: _x000b_Heat Exchange Heating Mode: by hot water or hot air.

Steam Mixing Heating Mode: steam is mixed into heated water by a steam mixer for heating mode.

Hot Water Mixing Heating Mode: high-temperature water mixes with heated water for heating mode.

Electric Heating Mode: water can be heated directly through an electric heating tube.

Wall hanging type, to be installed on the side wall of the chamber or other convenient walls.

Eo Vaporizer

Two Installation Modes : ground based and wall mounted

Mainly is stainless steel, avoid easy to get rusted

Easy Maintenance: the heat exchange core inside the body can be taken out, cleaned and repaired separately.

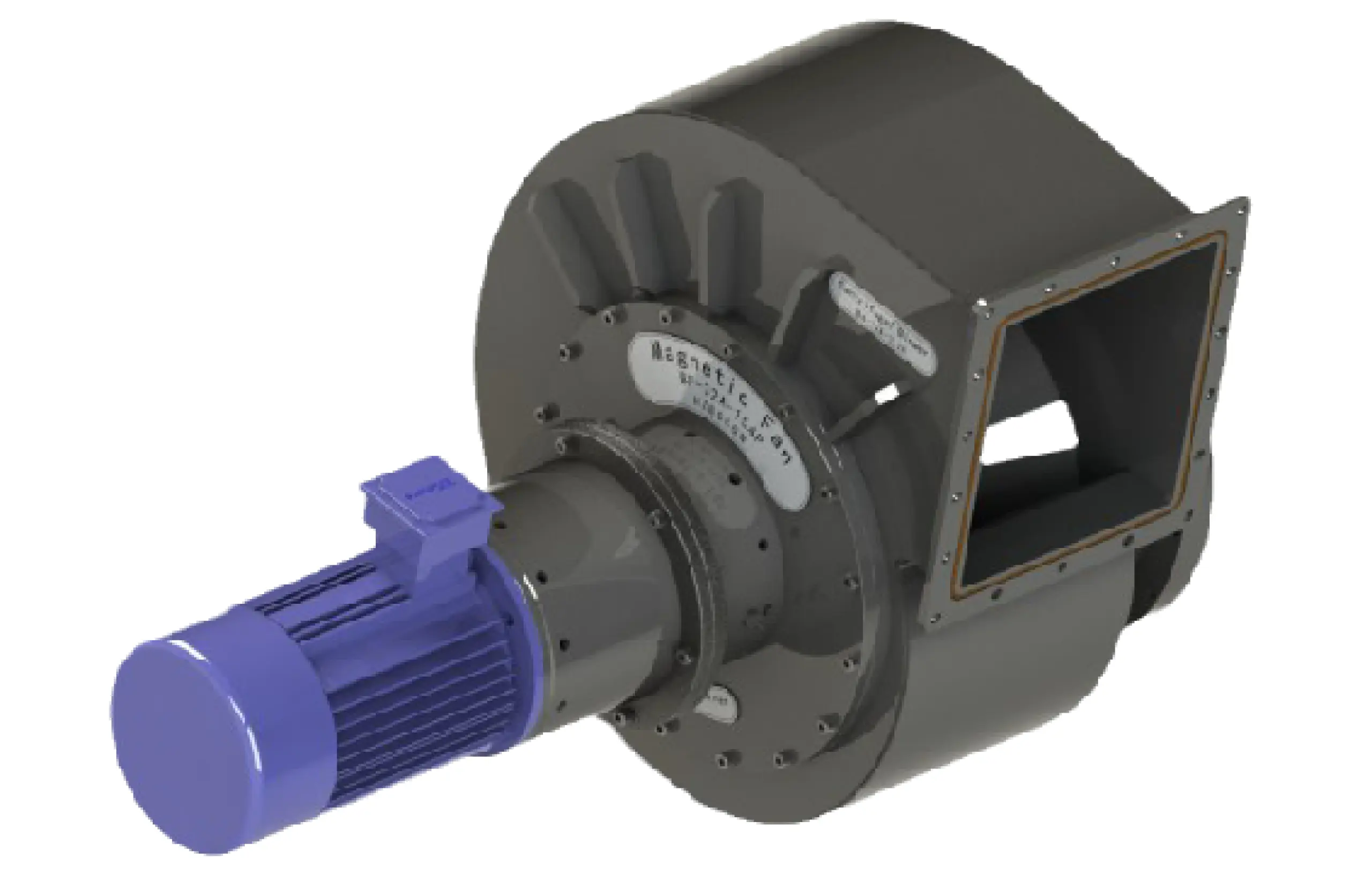

Magnentic Fan

BZBOCON design

SUS304 Stainless steel shell and impeller is pure aluminum

Magnetic coupled structure

Design life is at least 5 years. Continuous working time is two years.

Steam Generator

Pure water generator to prevent scale, provide easy cleaning and maintenance, energy saving and improve product reliability.

Automatic cleaning function.

Core components are made of stainless steel.

Steam pressure, liquid level display, automatic control of water level and the pressure in the furnace.

The electronic control and mechanical parts are integrated to facilitate installation and connection, and the electronic control parts are sealed and isolated.

Modular assembly design for easy expansion and maintenance.

Air Compressor

Brand: domestic-made

Nitrogen generator

Generally, more than 90% of EO gas need nitrogen protection. Sutures need nitrogen

Electrical Scale

Explosion-proof class: Ex ib IIC T3/T4 Gb

Selection of intrinsic safety battery pack, explosion-proof grade: Exib IIC T3 Gb

Selection of intrinsic safety power supply, explosion-proof grade: Ex ib IIC T4 Gb

Display: 25mmLCD with backlight or 0.8"LED

Accuracy Level: OIML III

AD Conversion:∑-△, 24bit

Internal Code: 2,000,000

Minimum Resolution: 0.3μV/d

Excitation Voltage: 5VDC

Input Signal Range: -30mv~30mv

Drive Capacity: 6 350Ω resistance strain gauge sensors

Working Power Supply: AC/DC intrinsic safety power supply or intrinsic safety battery pack 7.2V4.8Ah

Working Environment Temperature: -10~40℃

Humidity: ≤85%R.H

Harmless Exhaust Fan

.jpg?x-oss-process=image/auto-orient,1/interlace,1/resize,m_lfit,w_2560,limit_0/quality,Q_75/format,webp)

0.55KW/AC380V 3P 50HZ, the actual use load is 0.2KW times.

.webp?x-oss-process=image/auto-orient,1/interlace,1/resize,m_lfit,w_2560,limit_0/quality,Q_75/format,webp)

.webp?x-oss-process=image/auto-orient,1/interlace,1/resize,m_lfit,w_2560,limit_0/quality,Q_75/format,webp)

.webp?x-oss-process=image/auto-orient,1/interlace,1/resize,m_lfit,w_2560,limit_0/quality,Q_75/format,webp)

.webp?x-oss-process=image/auto-orient,1/interlace,1/resize,m_lfit,w_2560,limit_0/quality,Q_75/format,webp)

.webp?x-oss-process=image/auto-orient,1/interlace,1/resize,m_lfit,w_2560,limit_0/quality,Q_75/format,webp)