What Is Eto Sterilizer?

Publish Time:2023-10-12

ETO sterilizer stands for Ethylene Oxide Sterilizer. It is a type of sterilization equipment used in the healthcare and pharmaceutical industries to eliminate microorganisms from medical devices, instruments, and supplies that cannot withstand high temperatures or moisture. Ethylene oxide gas is the primary sterilizing agent used in this process. ETO sterilizers are commonly used for items like surgical instruments, catheters, implantable devices, and certain types of packaging.

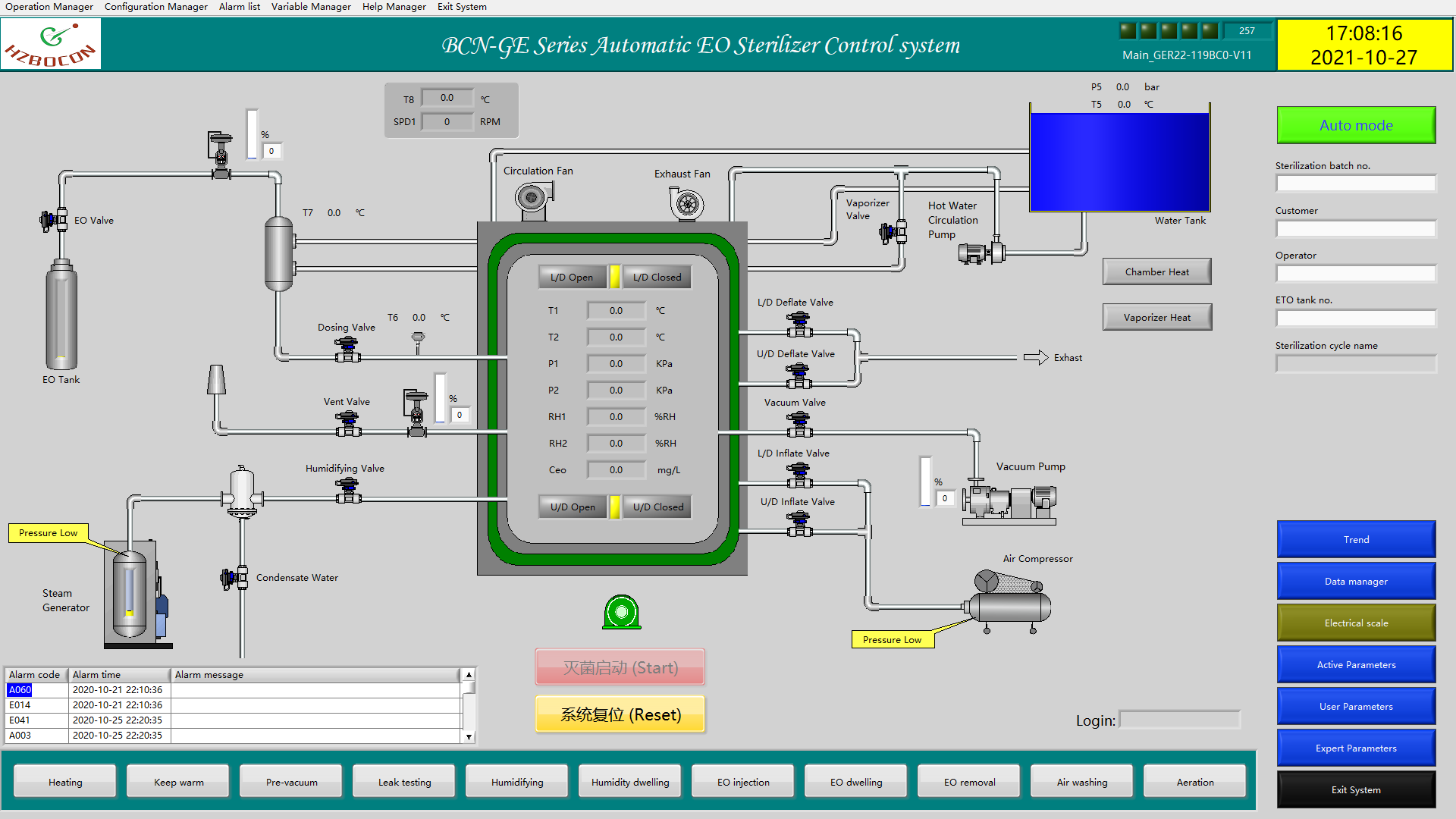

ETO sterilization works by exposing the items to be sterilized to an environment of ethylene oxide gas. The process typically involves the following steps:

Pre-conditioning:

The items to be sterilized are placed in the chamber or in a pre-heating room, (including heating, keeping warm, and humidifying)

Pre-vacuum:

The chamber is evacuated to remove air and moisture, creating a vacuum environment.

EO Injection:

Ethylene oxide gas is injected into the chamber, usually mixed with an inert carrier gas such as nitrogen or carbon dioxide to prevent the explosion.

Exposure:

The product is exposed to the ethylene oxide gas for a predetermined amount of time, which can vary depending on the type of materials being sterilized and the desired level of sterilization.

Aeration:

After the exposure time, the ethylene oxide gas is extracted from the chamber, and the items are aerated using aeration cycles involving vacuum and increased temperature. This is done to remove any residual gas (including EO removal, Air wash, Aeration).

Sterilizer time is depending on your product, mixed gas, single channel, or double channel.